By Julian Singer

The desperate need to store electricity has stimulated the development of some surprising techniques. One of these is based on the rusting of iron. The basic principle is that electrons are produced when iron rusts in the presence of water and oxygen. Conversely, if an electrical current is applied to rust the latter will release oxygen and water and revert back to pure iron.

The technique was explored by NASA in the 70’s but considered unsuitable for its needs. Now at least two companies are pursuing its use for grid-scale storage of electricity. Form Energy of Boston, Massachusetts, has developed a cell with an iron anode which on discharge is converted to rust by oxygen drawn in through the cathode and by the liquid electrolyte, while releasing electrons. To charge, electrical current is flowed through the cell and the rust is converted back to iron.

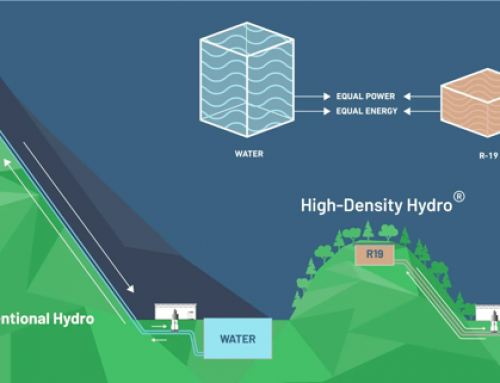

Form Energy’s vision of a future storage installation (www.formenergy.com)

A key component is the anode, which must allow oxygen to enter the cell but not allow the electrolyte to escape. Form Energy acquired the rights for such electrodes from Nant Energy of Arizona, who had developed them for its zinc-air batteries.

The iron-air battery is made from readily made materials, and hence should be cheap, and has a surprisingly high energy density. However, it is not suitable for cars because it does not release its energy quickly, as well as being too large. On the other hand, it is ideal for electricity storage because it can release its energy slowly over hundreds of hours. It is inherently safe because its components are non-flammable, unlike lithium-ion batteries.

The efficiency of the iron-air battery is not clear. Some reports indicate that is may be as low as 60 per cent, which compares poorly with up to 90 per cent for lithium-ion. Low efficiency means more energy is lost during the charge/discharge cycles. However, the key parameter is the levelized cost of storage, which takes into the account not only the efficiency but also the initial cost and the operational cost. Form Energy hopes to reduce this to an amazingly low $20 per kWh, more than ten times less than lithium-ion.

The batteries are packaged as cells with fifty such cells in a container the size of two washing machines. These will be combined to give the storage required. A typical installation should be able to provide 10MW of power for 100 hours. This is not large in terms of power but it is exceptional in terms of the length of time. The space required is also considerable, at 3MW per acre, which means it is aimed at grid-scale storage by power companies rather than for wind or solar farm operators, let alone residential users. In practice, one would expect a power company to combine it with a lithium-ion battery pack, with the latter providing the instantaneous power and the iron-air battery providing the background.

The proof will not emerge for a few years. The company will start to build a full-scale manufacturing facility in West Virginia this year which is expected to be commercial in 2024. Meanwhile outside its R&D facility in Massachusetts it has testing and pilot manufacturing facilities in Pennsylvania and California. The company has also developed grid-modeling software to help its eventual clients understand how much storage they will need.

Such ambitious plans need plenty of funding, but in this they have so far been successful. The company is privately owned, but early investors have included Bill Gates and the large steel manufacturer Arcelor Mittal. It has raised over US$800 million, including US$450 million in its latest financing round in October 2022. Although it spent over four years developing its cell, it is moving very fast from laboratory prototype to full scale commercial application. However, the CEO is Mateo Jaramillo, who previously led Tesla’s stationary energy storage programme, so he should know a thing or two.